A passion and process for

solving challenging problems

A passion and process for

solving challenging problems

A passion and process for solving challenging problems

A passion and process for solving challenging problems

A passion

and process for solving challenging problems

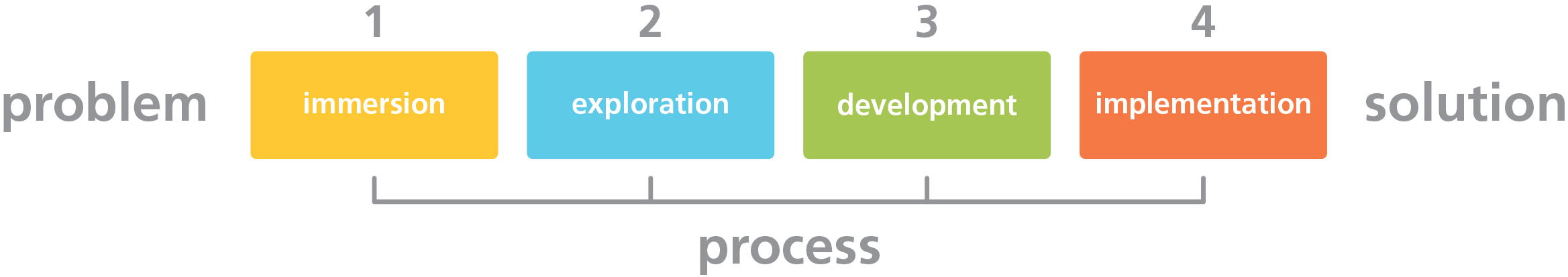

FactorsNY's proven development process is structured in a phased manner to assure optimal outcomes. Our methodology is flexibly customized within the process to most efficiently meet individual program objectives. Program plans are tailored to selectively apply the most effective research and development methods to expediently reveal, resolve and solidify extraordinary outcomes.

Our process is consistent with FDA Design Control Guidance for medical device development to support regulatory control and submission requirements. Emerging concepts and conclusions are verified and refined throughout the process to validate development decisions.

We work closely with our clients to coordinate collaborative team efforts to complement clients' in-house expertise. We work with an extensive network of quality certified manufacturers, with whom we’ve produced hundreds of successful products.

What's the problem?

1. Have an unmet need?

2. A formidable challenge?

3. An unsatisfying experience?

Recognizing an unmet need is the foundation of innovation.

Achieving a sound understanding of a problem initiates a path to success.

What's the problem?

1. Have an unmet need?

2. A formidable challenge?

3. An unsatisfying experience?

Recognizing an unmet need is the foundation of innovation.

Achieving a sound understanding of a problem initiates a path to success.

What's the problem?

1. Have an unmet need?

2. A formidable challenge?

3. An unsatisfying experience?

Recognizing an unmet need is the foundation of innovation.

Achieving a sound understanding of a problem initiates a path to success.

What's the problem?

1. Have an unmet need?

2. A formidable challenge?

3. An unsatisfying experience?

Recognizing an unmet need is the foundation of innovation.

Achieving a sound understanding of a problem initiates a path to success.

What's the problem?

1. Have an unmet need?

2. A formidable challenge?

3. An unsatisfying experience?

Recognizing an unmet need is the foundation of innovation.

Achieving a sound understanding of a problem initiates a path to success.

In need of a solution?

1. We thrive on solving complex problems.

2. We create value resolving exceptional products.

The most obscure problems can be the most satisfying to resolve.

The most rewarding design efforts produce smiles as well as profits.

In need of a solution?

1. We thrive on solving complex problems.

2. We create value resolving exceptional products.

The most obscure problems can be the most satisfying to resolve.

The most rewarding design efforts produce smiles as well as profits.

In need of a solution?

1. We thrive on solving complex problems.

2. We create value resolving exceptional products.

The most obscure problems can be the most satisfying to resolve.

The most rewarding design efforts produce smiles as well as profits.

In need of a solution?

1. We thrive on solving complex problems.

2. We create value resolving exceptional products.

The most obscure problems can be the most satisfying to resolve.

The most rewarding design efforts produce smiles as well as profits.

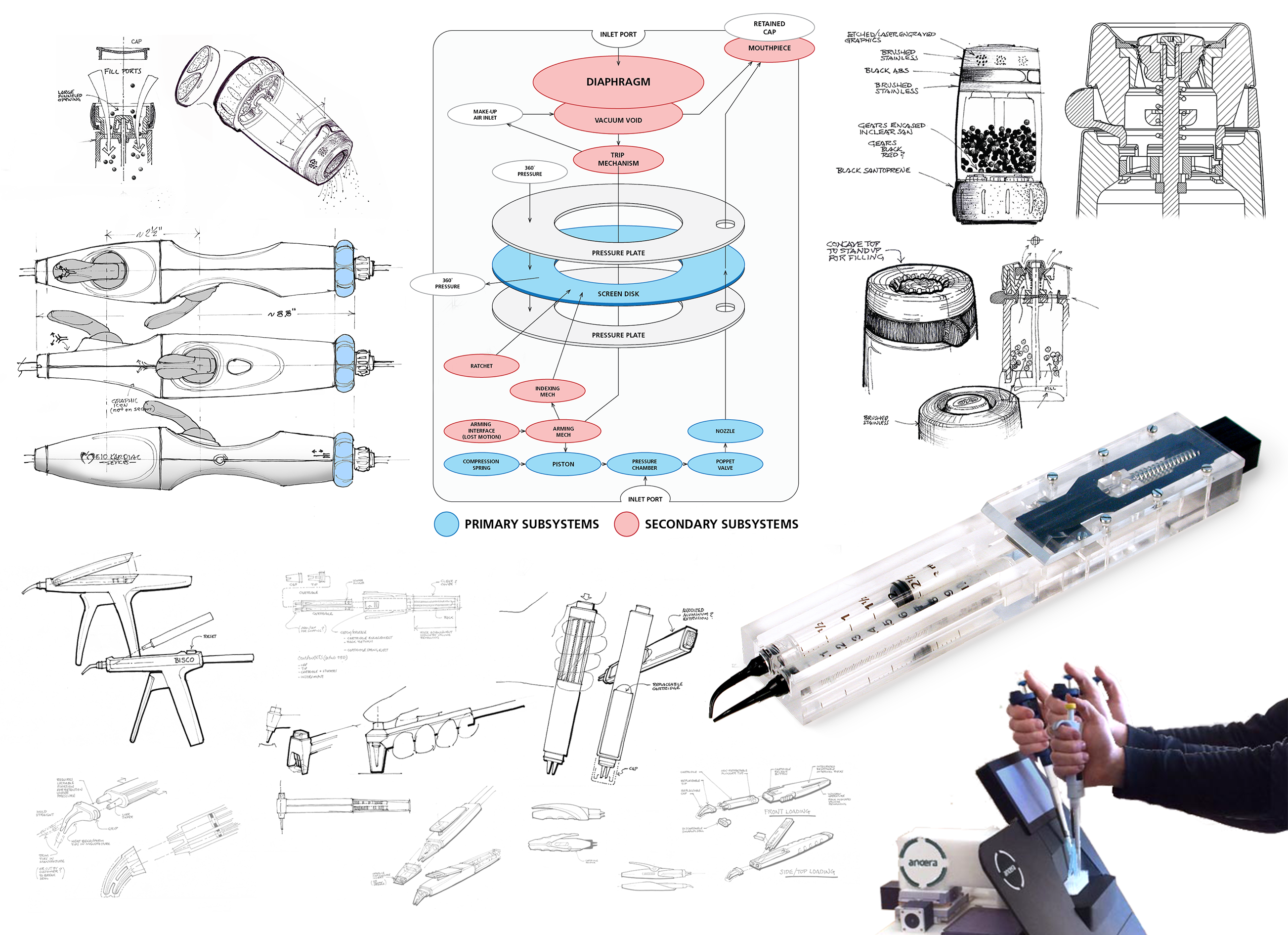

Effective outcomes are built upon solid inputs. Programs are initiated by rapidly acquiring a sound foundational understanding of product specific use, markets, and technologies - upon which to make intelligent decisions and innovative breakthroughs.

Decades of information gathering, user study experiences and medical/surgical observations, facilitate our fast paced understanding of the user-product interaction and the resolution of problems presented in bringing products from mind to market.

FactorsNY assimilates the collective knowledge to reveal unique visionary opportunities, develop a design strategy and establish essential design requirements.

methods include:

Direct Observation

Focus Groups

Procedural Task Analysis

Operatirend Research

Competitive Product Analysis

Patent Seaonal Sequence Studies

Technology Assessments

Market Trches & Reviews

Experience Mapping

User Interviews/Questionnaires

Anthropometric Studies

Ergonomic Assessments

Problem Definition

Design Input Requirements

Intelligent concepts are built upon discoveries revealed through 'immersion'. With focused purpose and open mind, we seek exciting solutions to challenging issues. We conceive compelling products that are simple and implicit to use, satisfy and instill value. We embrace the unexpected and always value user satisfaction most highly.

In this early phase of development FactorsNY will laterally explore a range of alternative conceptual approaches to most effectively meet defined performance criteria. A multitude of inter-related factors must be concurrently considered as we envision overall system configuration, appearance and essential functional requirements.

Preliminary sketches, conceptual mock-ups, photo-realistic virtual models, and/or functional feasibility studies are prepared to visualize the look and performance of emerging concepts. Evolving concepts are challenged, assessed and iteratively refined toward establishing preferences, proof-of-concept, and selection of a most promising direction(s) for ongoing design and engineering development.

methods include:

Creative Brainstorming

Visualization

2D & 3D Sketching

Ideation & Invention

Conceptual Mock-ups

Configuration Studies

Appearance Studies

Photo-realistic rendering

Feasibility Fixture Fabrication

Functional Testing

Proof-of-Principle Models

Key Thought Leader feedback

Having selected a preferred direction from the range of explored approaches, our focus is now intently narrowed upon translating conceptual visions into fully resolved manufacturable products. Strategies are devised for overall system configuration, melding form and function as the design comes to life.

Individual components are designed and engineered as cohesive integrated assemblies to perform specific intended purposes - while concurrently determining optimal use of materials, cost effective manufacturing processes, and nuances of fits and finishes. Throughout the development process we remain committed to enhancing the user experience.

Our use of virtual 3D CAD modeling accelerates the program toward realization. Evaluation of physical prototypical models, fabricated by in-house 3D printing and outsourced additive and CNC processes, are essential to verifying functional performance and aesthetic appeal.

methods include:

3D CAD Modeling

Mechanical Detailing

Design for Manufacturing & Assembly

Production Costs Assessment

Rapid Prototyping

Traditional Model-Making

Color, Finish & Graphic Detailing

Packaging and graphics

Prototype Fabrication & Assembly

Failure Mode & Effect Analysis

Data Acquisition & Dynamic Analysis

Static/dynamic Force Analysis

Customer feedback studies

Documentation is key to the accurate transfer of product designs to manufacturers for efficient production implementation. Production tooling is machined directly from our precisely modeled 3D CAD geometry. Our 2D part drawings include materials, finishes and process specifications. Dimensional tolerances enable quality control of critical features and fits. We communicate with manufacturers throughout tooling, review first article parts, verify assemblies and support final product validation.

Years of experience provide us with an expanding network of vendor resources from which to recommend domestic and off-shore manufacturers with whom we've had prior positive relationships.

We work with outside patent attorneys to prepare provisional and non-provisional patent claims, descriptions and drawings.

Clients and their customers benefit from our ceaseless commitment to design excellence at FactorsNY.

methods include:

3D Geometry for Tooling

2D Part Documentation

Tolerance Studies

Vendor Recommendations

Finishing Specifications

Materials & Process Specs

Cost & Assembly Quotations

Assembly Fixtures & Set-ups

Vendor Liaison

First Article Reviews

Part & Assembly Checks

Process Validation

Patent Preparation Support

Packaging & graphics

29 Broadway, 16th Floor, New York, NY 10006 | 212.943.1600 | info@factorsny.com

29 Broadway, 16th Floor, New York, NY 10006 | 212.943.1600 | info@factorsny.com

29 Broadway, 16th Floor | New York, NY 10006

212.943.1600 | info@factorsny.com

© Copyright FactorsNY 2025, All rights reserved

© Copyright FactorsNY 2025, All rights reserved