atraumatic morcellation of full thickness skin graft

TissueMil Technologies

Autologous Skin Grafting System

The Challenge Dr. Thomas Davenport, MD, FACS, came to us with the vision of enabling surgeons to heal chronic open wounds with a patient's own skin tissue.

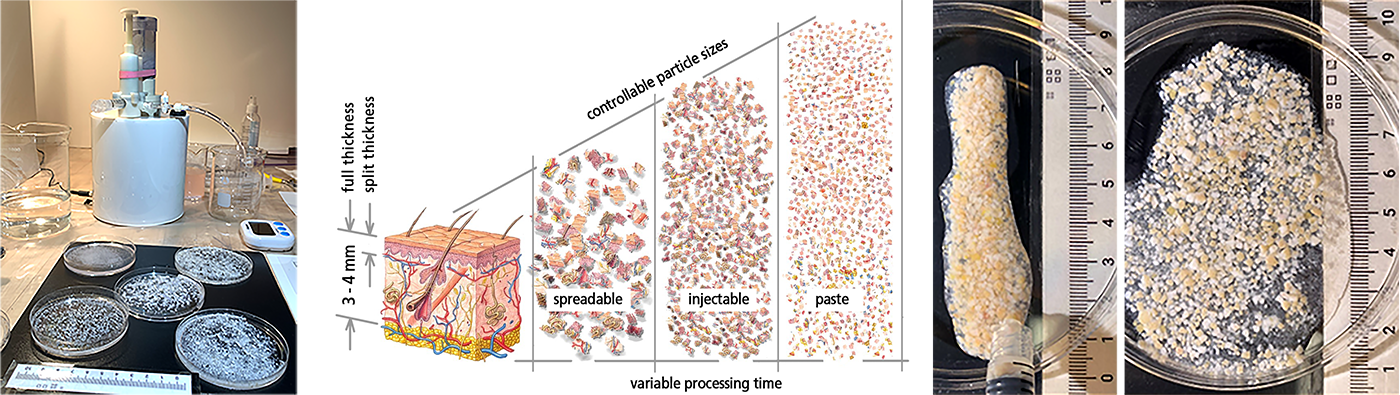

Underwhelmed by the performance of other products, he asked: Can we create a commercializable device to rapidly and atraumatically process small excised portions of full thickness abdominal tissue into a dispensable suspension of finely morcellized autologous micrografts - as a bedside treatment?

The Solution A small tissue graft, harvested from an easily suture closed site, is processed within a few minutes into an abundance of highly viable tissue particulates, able to cover a much larger area than the original site.

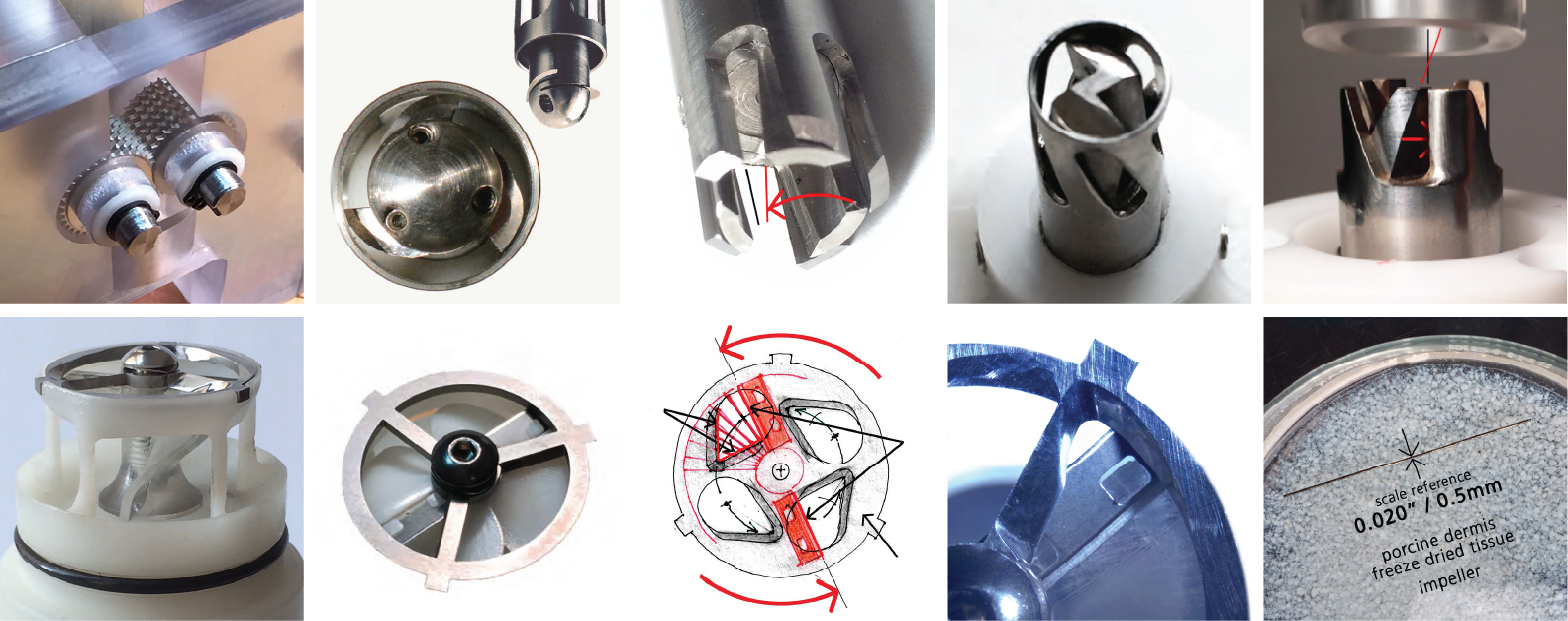

Build and test With years of prior dermal device development experiences, FactorsNY embarked upon exploratory detailing, machining, fabricating and bench testing experimental fixtures using in vitro skin graft tissue forms. Each of many experiments facilitated lessons learned toward identifying promising principles - foundational to achieving physical performance and the basis for new and novel proprietary technology.

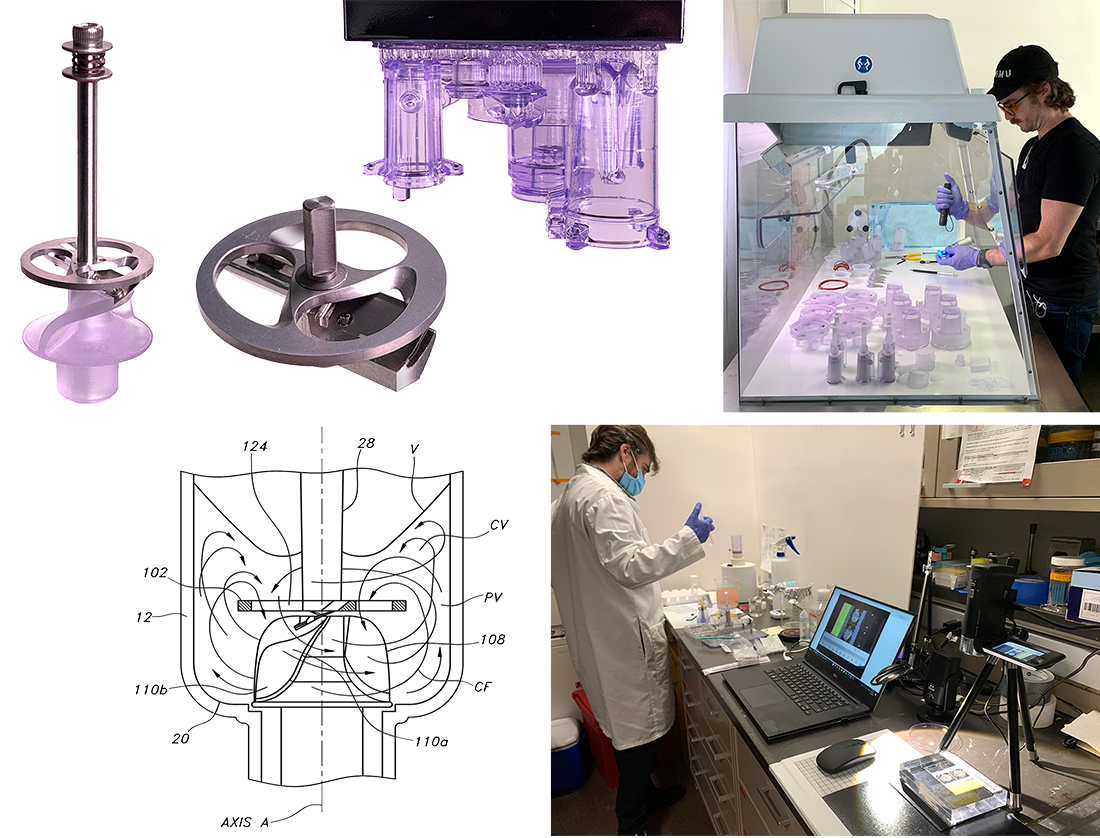

Design development 3D printed bio-polymer & machined stainless steel developmental models, methods, processes and patents were evolved in concert with frequent in-hospital lab studies using freshly harvested full thickness dermal tissue.

System evolution Progressively refined functional fixtures were evolved toward defining an efficient system of sterilizable single-patient-use disposables, driven upon a reusable base drive.

It looks like a vortexing flurry of snowflakes being cut 'on the fly' into progressively smaller particles

Uniquely devised flow and cutting dynamics are essential to the atraumatic tissue manipulation. Fluid suspended tissue is continuously recirculated within trilobular vortices through cyclically incising opposed blades, to be repeatedly sliced into progressively smaller particulates.

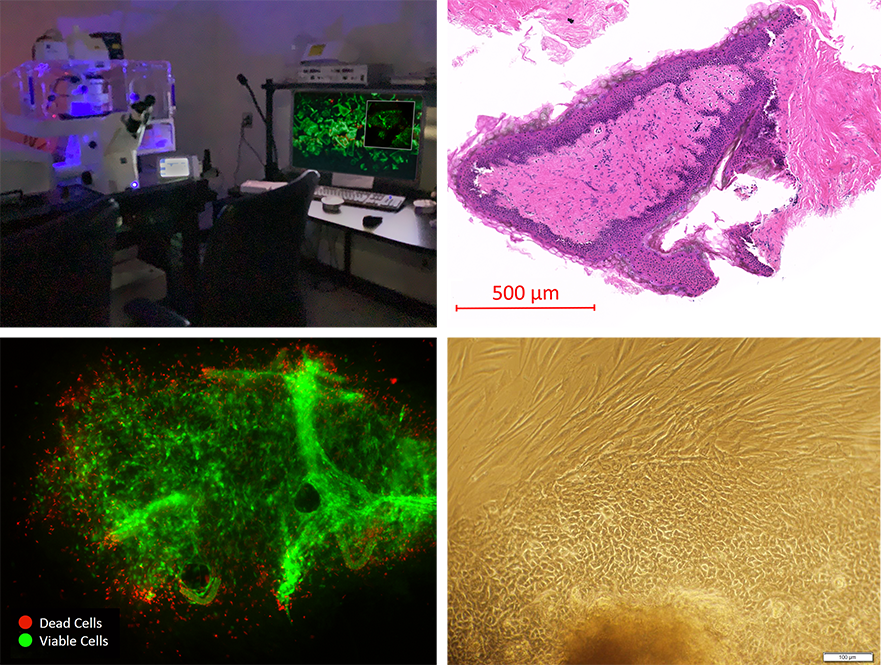

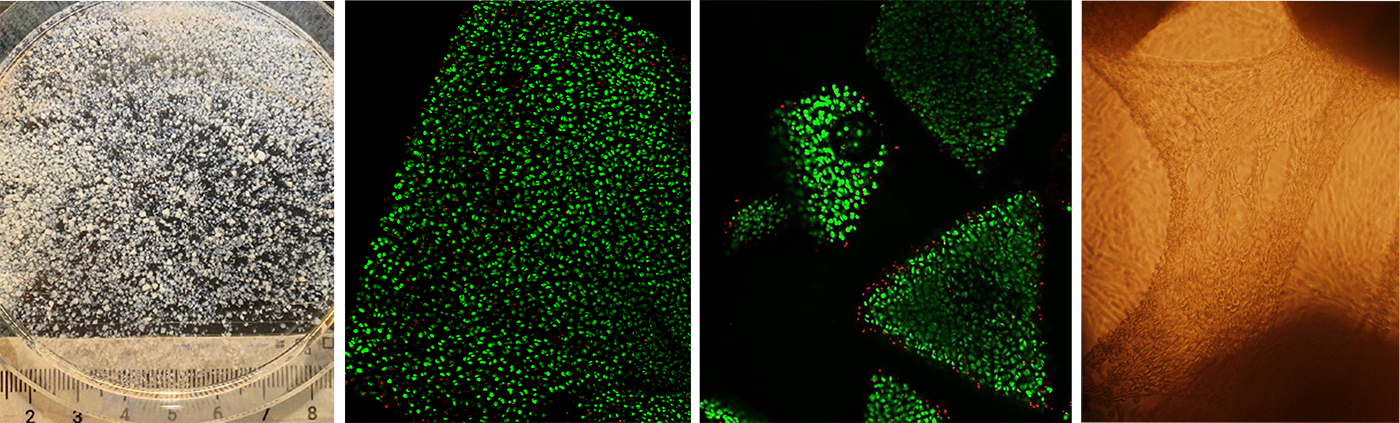

Process Verification FactorsNY processed freshly harvested human abdominoplasty tissue for confocal microscopy at The Feinstein Institutes for Medical Research to verify highly viable cell output.

Red/Green (dead/live) cell imaging revealed high percentages of viable cells. H&E staining also revealed abundant viable cell and tissue histology (dark purple dyed).

Rapid cellular outgrowth was observed filling gaps between incubated morcels, with layers of keratinocytes over feeder layers of fibroblasts creating thick multi-layers of tightly cobblestone patterned cellular outgrowth fully covering flask surfaces.

Bovine articular cartilage is similarly rapidly processable into progressively smaller highly viable micro-particles. A robust reparative mechanism is demonstrated by multilayered waves of migrating chondrocyte outgrowth bridging between morcels, completely colonizing cell culture flask surface plates within 3 weeks.

UPDATE: TissueMil Technologies has now progressed, with validated pilot production devices, into human clinical trials, regrowing patients’ own skin/tissues on otherwise chronically challenging to heal open wounds.

29 Broadway, 16th Floor, New York, NY 10006 | 212.943.1600 | info@factorsny.com

29 Broadway, 16th Floor, New York, NY 10006 | 212.943.1600 | info@factorsny.com

29 Broadway, 16th Floor | New York, NY 10006

212.943.1600 | info@factorsny.com

© Copyright FactorsNY 2025, All rights reserved

© Copyright FactorsNY 2025, All rights reserved